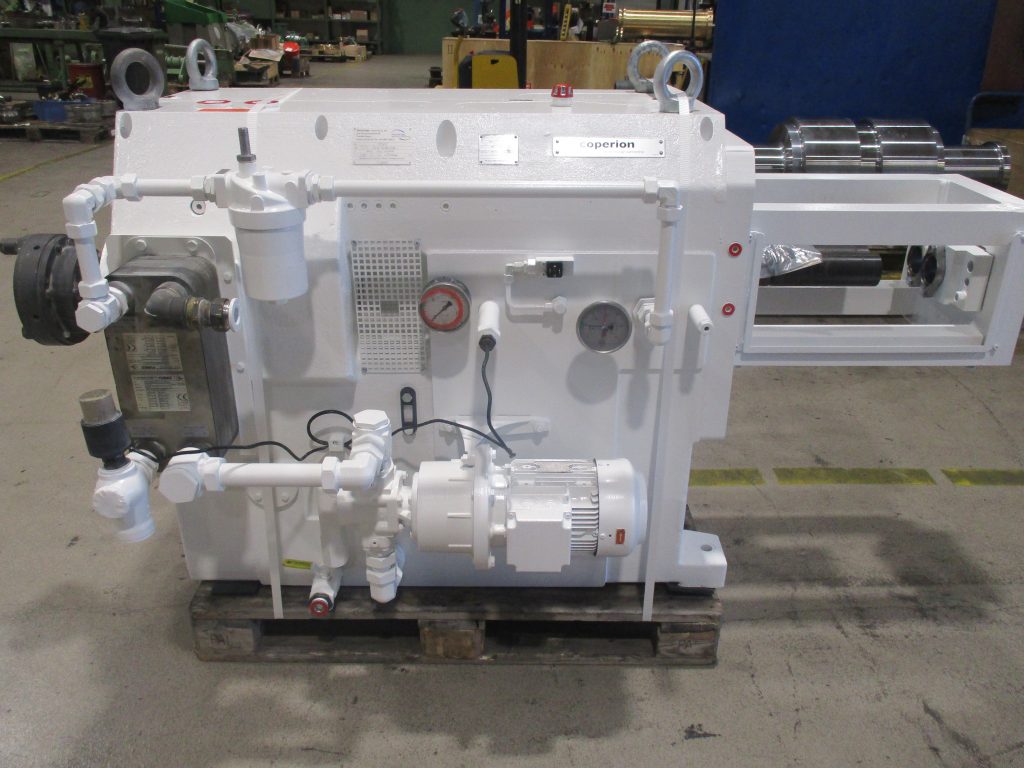

Additional information on the repair of the PIV extruder gearbox 76P 3850 CW from a Coperion extruder:

Gearbox ratio: i=5.07

Weight of the gearbox: 2,600kg

Output torque of the gearbox: 2x 3850Nm

Plant: Compounding plant

End product: Floor coverings

Damage found on the PIV extruder gearbox:

Twisted output shaft and a run-in seat of the shaft seal.

Measures taken as part of the repair of the PIV gearbox:

The output shaft was manufactured in advance and run-in seats of shaft seals were repaired by metallising.

Turnaround time for the entire gearbox repair: 14 days

During operation of his Coperion extruder, the customer noticed that the alignment of the two output shafts in the PIV extruder gearbox was no longer correct. There was obviously an overload in the PIV extruder gearbox, which led to the damage. A previous blockage of the extruder screws was suspected as the reason for the damage to the extruder gearbox.

As with most extruder operators, there are only very short downtimes of a few days during which such extensive repairs to extruder gearboxes can be carried out. Replacement extruder gearboxes are only kept in stock in a few cases due to the high cost of extruder gearboxes.

The twisted output shaft of the extruder gearbox is a toothed part that has to be milled, case-hardened and ground.

The manufacturing time for such spare parts for extruder gearboxes is therefore several weeks if the production of the replacement gearing can only begin after the VIP extruder gearbox has been dismantled.

Thanks to our many years of experience in the field of repairing extruder gearboxes from various extruder gearbox manufacturers and extruder manufacturers, we have the necessary information to be able to manufacture spare parts for extruder gearboxes in advance of a planned repair. The downtime of extruders due to gearbox damage can thus be reduced to just a few days.

After dismantling the defective PIV extruder gearbox, the existing production data of the spare part was compared again with the actual geometry of the installed output shaft using a 3D measuring system. This eliminated any deviations from the prefabricated shaft.

As part of the repair of the PIV extruder gearbox, in addition to the output shaft, the complete bearing set was replaced, the lubrication system including the motor was dismantled and overhauled, and worn fitting seats were metallised.

During assembly, the output shafts were carefully adjusted in relation to each other to ensure that the extruder screws would later run without contact.

Our customer was able to put the Coperion extruder back into operation shortly before the end of the planned downtime.

You can find more information about our industrial gearbox services at

Service and maintenance of gearboxes

Repair of gearboxes

Rebuilding and new construction of gearboxes

Online monitoring of gearboxes for incipient damage

Call us on +492841-1802.80 if you would like to speak to our gearbox specialists. We look forward to hearing from you.